Page 3 - 2017-07-CFR2

P. 3

Some issues that can affect the flooring material are:

High amounts of natural products included in the

core material affected by changes in relative hu-

midity in the slab and ambient air space.

Uncontrolled environment (cold going to hot and

vice versa)

High amounts of passive solar heat directly on

the floor – a further comment about this later

Aftermarket radiant heating systems generating

high amounts of heat equating to compressed

edges

Underlayment not properly acclimated, either too

wet when installed or high variance in the sub-

floor…again high swings in heat and humidity

which can affect the substrate material and hence

the flooring or the underlayment itself being un-

stable or moving.

Uneven tension in the flooring material is com-

mon and can be created by the core material, the

print layer (decor’ paper), wear layer, and ure-

thane if applied.

And let’s not forget chemical adhesive removers

or abatement chemicals which can affect the

flooring whether glued direct or floating.

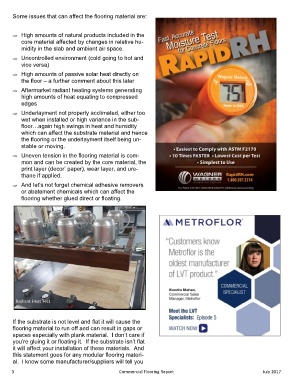

Radiant Heat Test July 2017

If the substrate is not level and flat it will cause the

flooring material to run off and can result in gaps or

spaces especially with plank material. I don’t care if

you’re gluing it or floating it. If the substrate isn’t flat

it will affect your installation of these materials. And

this statement goes for any modular flooring materi-

al. I know some manufacturer/suppliers will tell you

3 Commercial Flooring Report